Stolz & Seng – Success story from the injection molding expert

Optimized competitiveness with the business model, production environment and employee motivation!

Company

Stolz & Seng Kunststoffspritzguss und Formenbau GmbH

Location

Donaueschingen, Germany

Emphasis

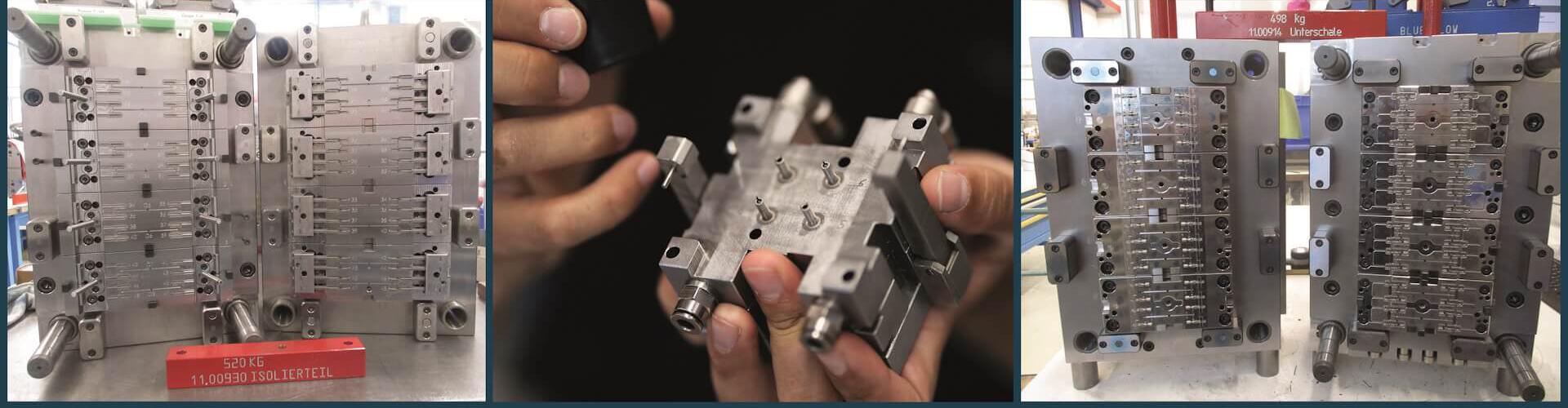

Mold manufacturing

Plastic injection molding

Project elements:

Strategic consulting for:

1) Business model/future-oriented alignment

2) Optimization of production environment

3) Employee motivation

Industry

Mold manufacturing

First published

2023

Stolz & Seng Kunststoffspritzguss und Formenbau GmbH

Location

Donaueschingen, Germany

Emphasis

Mold manufacturing

Plastic injection molding

Project elements:

Strategic consulting for:

1) Business model/future-oriented alignment

2) Optimization of production environment

3) Employee motivation

Industry

Mold manufacturing

First published

2023

5-axis, electrodes, hard milling, soft milling: Now each of our employees can professionally operate every machine

Christian Seng, Managing Director, Stolz & Seng Kunststoffspritzguss und Formenbau GmbH

Just a few adjustments are enough

The desire of Reinhard Stolz and Christian Seng, the two owners of Stolz & Seng GmbH, has always been to adapt to meet the needs of their enterprise customers. This has led to growth over m any years and a resulting expansion of their portfolio. The following article describes why the successful plastic injection molder and mold manufacturer – which was heavily impacted by the COVID-19 crisis – decided to work with Tebis Consulting to examine and optimize its business model, machinery and employee motivation.

"Big on small" is the motto of the company established in 2003 and still managed by Christian Seng, one of the initial founders. With a current portfolio of 45 injection molding machines, the focus is clearly on injection-molded parts.

"Big on small" is the motto of the company established in 2003 and still managed by Christian Seng, one of the initial founders. With a current portfolio of 45 injection molding machines, the focus is clearly on injection-molded parts.

Focus on injection molding

The company's primary revenue, which started with half die manufacturing and half injection molding orders, now clearly lies with injection molding, primarily based on 3K multi-component technology and micro injection molding. Stolz & Seng manufactures several million parts per year, including microcomponents weighing just 0.002 g.

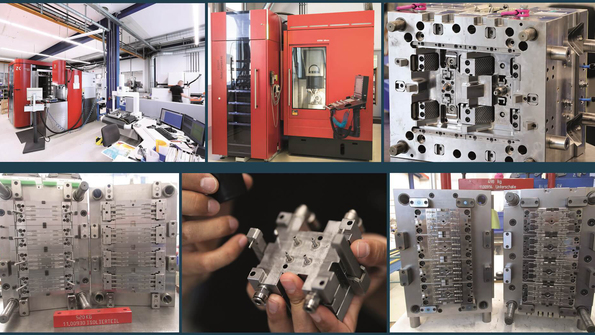

A modern production environment

Seng recalls: "We planned to modernize our equipment to meet the increasing requirements. But we got into difficulties and got lost in the plethora of offerings on the market." The entrepreneur's wish-list included a modern 5-axis machining center for the transition from manual processing to automation. He says that, "The team was great and they were highly motivated; that wasn't the reason that our machine-hours remained far below our expectations. The problem lay in the outdated work environment: for example, pallets were still changed out by hand. And it also lay in traditional work methods. Among other things, each team member was a specialist on their machine – but only on that machine. This meant that order peaks and vacations unfortunately resulted in delays, and that often took us to our limit."

After some consideration, it was decided to obtain a professional external opinion, and the choice was made for Tebis Consulting. Tebis Consulting advises companies in the machining industries and sees itself as an integral part of the die, model and mold manufacturing industry:

Since its founding (2015), 800 small and medium-sized companies have relied on the expertise of this VDWF member – including Stolz & Seng.

After some consideration, it was decided to obtain a professional external opinion, and the choice was made for Tebis Consulting. Tebis Consulting advises companies in the machining industries and sees itself as an integral part of the die, model and mold manufacturing industry:

Since its founding (2015), 800 small and medium-sized companies have relied on the expertise of this VDWF member – including Stolz & Seng.

The team develops its ideal work environment

Markus Rausch, Consultant at Tebis Consulting

At first glance, the concept from Tebis Consulting consultant Markus Rausch contained the traditional ingredients for consulting: The on-site analysis was followed by meetings and a workshop on how to develop the ideal work environment. What was unusual is that Rausch didn't call in management; rather, he worked with the CNC millwrights and machine operators. These employees were able to enumerate all the bottlenecks when working together and in the task sequence, they were intimately familiar with the strengths and weaknesses of the existing machinery – and they could very specifically list their requirements for new machines. <br /> Christian Seng was enthusiastic: "The discussions with Markus Rausch were highly constructive and team-building; a unique dynamic was certainly developed. The presentation of his proposals to me and the team of die manufacturing managers included a first-class list of our technical requirements. Once the basic decisions were made, the team obtained quotations, discussed everything with the tradespeople and independently organized the complete installation of the machine. Another improvement initiated by Rausch was also very positively received by the team: a modern assignment of roles that’s suited to the new automated work environment.<br />

A modern role concept for greater flexibility

The users at Stolz & Seng trained each other on the different machines, increasing flexibility for everyone involved. "5-axis, electrodes, hard milling, soft milling: Now each of our employees can professionally operate every machine," says Seng.

These modern work methods consistently landed on fertile ground at Stolz & Seng. The team is currently looking for a suitable wire EDM machine, and the users are acting with no support from Rausch: They’re drawing on the selection method they’ve learned. Another project in the planning stage for the near future – to increase the level of automation – includes a workshop for classifying the parts.

These modern work methods consistently landed on fertile ground at Stolz & Seng. The team is currently looking for a suitable wire EDM machine, and the users are acting with no support from Rausch: They’re drawing on the selection method they’ve learned. Another project in the planning stage for the near future – to increase the level of automation – includes a workshop for classifying the parts.

A look ahead

The team was highly motivated: Florian Mäder, Andreas Klotz, Björn Stökle (front row) Benedikt Zeller, Tobias Haack, Stefan Bäurer (back row), milling machine operators at Stolz & Seng Kunststoffspritzguss und Formenbau GmbH

"Our decision some years ago to focus on injection molding laid the foundation for our success, and it still feels right today," Seng explains. The Managing Director continues: "Still, we also need to consider where we’re going in the future. Conditions in the die and mold manufacturing industry remain tough, and if we have an energy crisis, for example, plastic injection molding is directly affected. Therefore, we have to remain open to new directions and concepts." He’s currently working intensively with Tebis Consulting and several other industry representatives to address the question of how the present business model can be made more viable for the future and expanded. A new approach is being considered but isn’t ready for discussion. Seng is sure that he’ll be able to communicate it soon, and he refers to Tebis Consulting:

One of the greatest advantages of our collaboration is definitely the rigor of the consultants. They ensure that we stay on the ball and never lose sight of our goals.