Tebis Consulting recommends industry to address sustainability at an early stage

Sustainability as a competitive advantage: Tebis Consulting positions itself at Moulding Expo

Tebis Consulting at Moulding Expo (May 6-9 in Stuttgart, Germany): at the joint booth with VDWF, Hall 6, booth E40

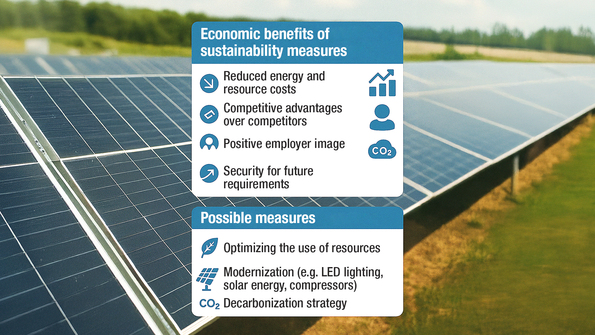

Stuttgart, May 6, 2025 – Tebis Consulting, the consulting unit of Tebis AG, has developed consulting in sustainability that is specifically tailored to the needs of medium-sized manufacturing companies. Tebis Consulting Sustainability Expert Philipp Sander will be presenting the offered services to visitors at the VDWF joint booth at Moulding Expo (Hall 6, booth E 40) and appeals to industry members to quickly address the associated challenges and opportunities: "Many companies underestimate the economic benefits of sustainability. It's not just about image or green symbols, it's about tangible savings, minimizing risk and security for the future. Companies that start now by operating more sustainably, reducing resource consumption and taking advantage of existing funding opportunities are securing decisive competitive advantages."

The requirements profile for suppliers is changing

The die, model and mold manufacturing industry is under significant economic pressure. Philipp Sander also sees that rising costs for energy and materials, increasing regulatory requirements and the ongoing skilled labor shortage pose major challenges for many small and medium-sized companies. The sustainability consultant from Tebis Consulting explains: "New opportunities are also arising especially from this situation. Because companies investing in sustainability today can not only reduce their operating costs, but can also position themselves strategically in the market, as an attractive and reliable partner that is viable for the future."

The volatile energy prices of recent years have already forced many companies to rethink their strategy. This is compounded by bottlenecks and price increases for resources and materials. Looking at the legal situation, we can see: Sustainability is also becoming increasingly mandatory on a European level, whether through the planned EU supply chain law, the growing requirements for transparency in the value chain or the continuing expansion of sustainability reporting. In many cases, major customers are already requesting specific data on CO₂ emissions or resource use in order to meet their own reporting obligations. Suppliers who are not prepared for this run the risk of being passed over in contract awards.

Sustainability increases attractiveness and reduces costs

But sustainability has long been more than just a matter of compliance. It gives companies the chance to deliberately reduce their consumption of energy and resources and take advantage of subsidies, thereby not only improving their own profitability but also increasing their visibility for customers, business partners and potential new employees. Younger specialists in particular are placing increasing importance on value-based corporate management. Companies that credibly implement sustainable measures not only improve their attractiveness as an employer, but also establish identification and loyalty.

Consulting with an understanding of the industry: sustainable, cost-effective and feasible

Philipp Sander observes: "In practice, however, many companies lack the necessary orientation. Which measures make sense? Where is it best to start? How can sustainability be reconciled with the requirements of an operating business? This is precisely where our specialized sustainability consulting comes in, tailored to the needs of companies in the die, model and mold manufacturing industry. One question is always central here: How can sustainability be implemented cost-effectively, realistically and practically?

Immediately evident savings potential & state subsidies

A key focus of Tebis Consulting's new offering is optimizing the use of resources. Energy flows and material consumption are systematically analyzed in an initial status assessment. It often becomes apparent that simple measures can yield significant savings potential. For example, converting to LED lighting, replacing outdated compressors or improving the control of machines and auxiliary units can yield noticeable cost reductions. Such modernizations are often eligible for subsidies, such as through programs from the German Federal Office for Economic Affairs and Export Control (BAFA) or the bank KfW. The service provided by Tebis Consulting not only includes a technical evaluation, but also support in selecting and applying for appropriate funding.

Decarbonization with a sense of proportion

The question of decarbonization will also receive more attention over the long term. How can CO₂ emissions be systematically reduced, in operations, in the supply chain and, over the long term, also in use of the products? A refined decarbonization strategy does not necessarily have to employ radical changes. It's much more about identifying viable development paths, setting priorities and integrating the necessary steps in the existing corporate strategy. This is usually based on greenhouse gas footprinting following established standards such as the Greenhouse Gas Protocol. This creates transparency regarding the sources of emissions in the company.

1 A study by the Fraunhofer Institute for Systems and Innovation Research (ISI) and the Wuppertal Institute estimates that measures to increase material efficiency in Germany's manufacturing industry could potentially cut costs by more than 7 billion euros.

wupperinst.org/p/wi/p/s/pd/73

Sustainability reports in accordance with the VSME standard: an easy way to get started

For companies that want to – or have to – document and communicate their sustainability performance in a structured way, an expedient place to start is by preparing a sustainability report in accordance with the VSME standard. This is also particularly appropriate for small and medium-sized companies. This provides a practically oriented alternative to complex ESG frameworks and helps to systematically record and present key topics such as the environment, social issues, corporate governance and the supply chain. The key advantage: The VSME standard enables the creation of a structured sustainability report with manageable effort, which can be used both internally as a management tool and externally for positioning. It also serves as useful preparation for possible future reporting obligations.

Act now to remain competitive tomorrow

Overall: Sustainability is not an end in itself, but rather is a strategic instrument that, when used correctly, generates economic benefits, reduces risks and opens up new opportunities. For companies in die, model and mold manufacturing, the right time to set the course is now. Philipp Sander: "Companies that act early not only gain a clear competitive advantage, but also strengthen their own resilience in an increasingly dynamic market environment. The appropriate tools, concepts and funding are available – they just have to be applied in a targeted manner."

Sustainability consulting from Tebis Consulting

The practical consulting is targeted specifically for medium-sized manufacturing companies. The focus is on GHG footprinting, reducing emissions along the value chain, compliance with statutory reporting obligations and preparing for the sustainability requirements of enterprise customers.

All measures are divided into flexible modules, so the scope and costs can be controlled individually. The purpose and the implementation period are also agreed upon with the respective customer. The Tebis Consulting team works together with the corporate customer in step-by-step implementation.

Here are some typical sustainability projects with Tebis Consulting:

- Implementing a carbon footprinting and reduction strategy

- VSME standard: Implementation and reporting

- Energy efficiency and resource management in the production process

Philipp Sander has many years of experience as a consultant for companies in a wide range of industries. He emphasizes sustainability, greenhouse gas (GHG) footprinting, emissions reduction and support in preparing reports in accordance with VSME, CSRD and EU taxonomy specifications. In addition to his expertise in strategic consulting, he has a deep understanding of industry-specific challenges. He focuses not only on preparing companies for legal requirements, but also on highlighting opportunities and possibilities and positioning them as long-term sustainability pioneers.

Tebis Consulting Consultant Philipp Sander has many years of experience in sustainability and emissions management and implements practical sustainability projects with clear economic added value for Tebis Consulting's corporate customers.